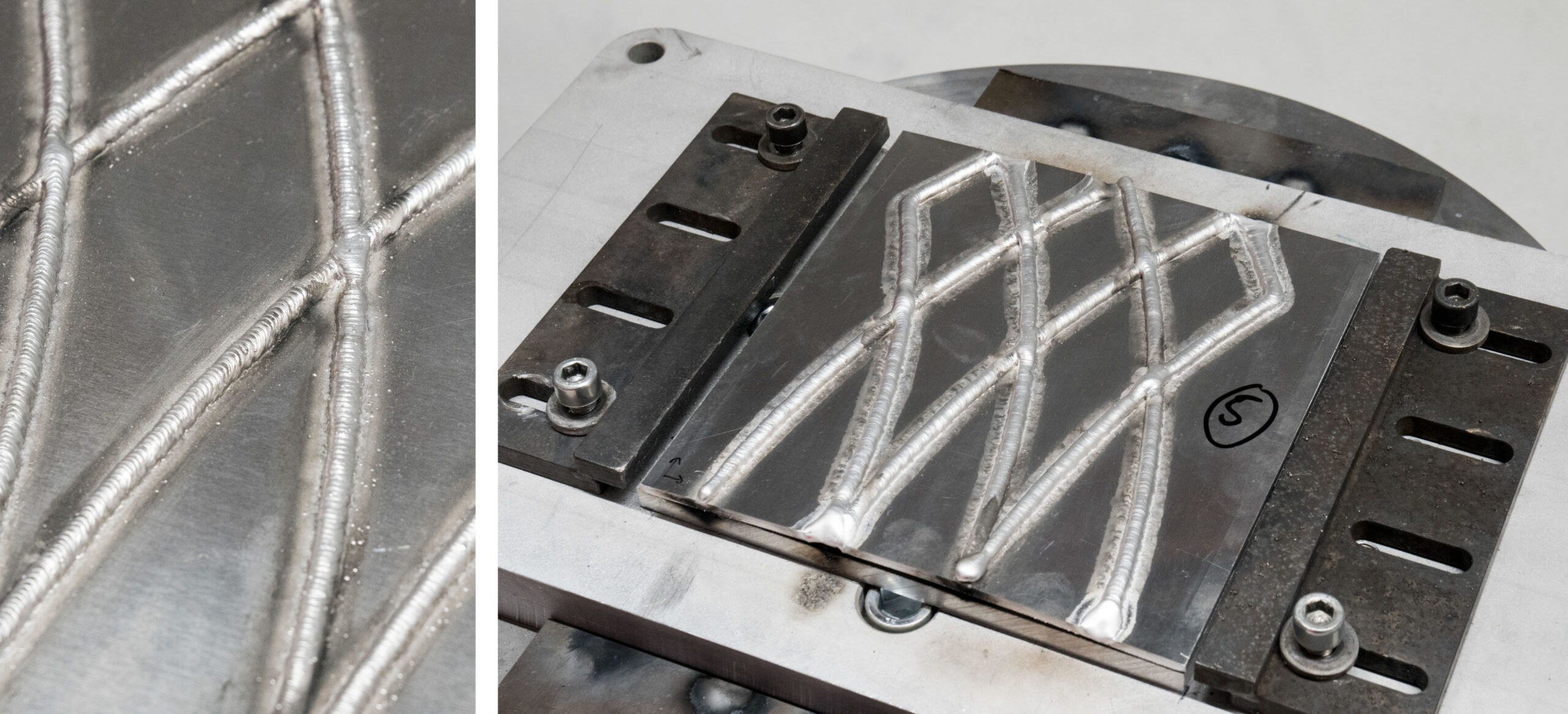

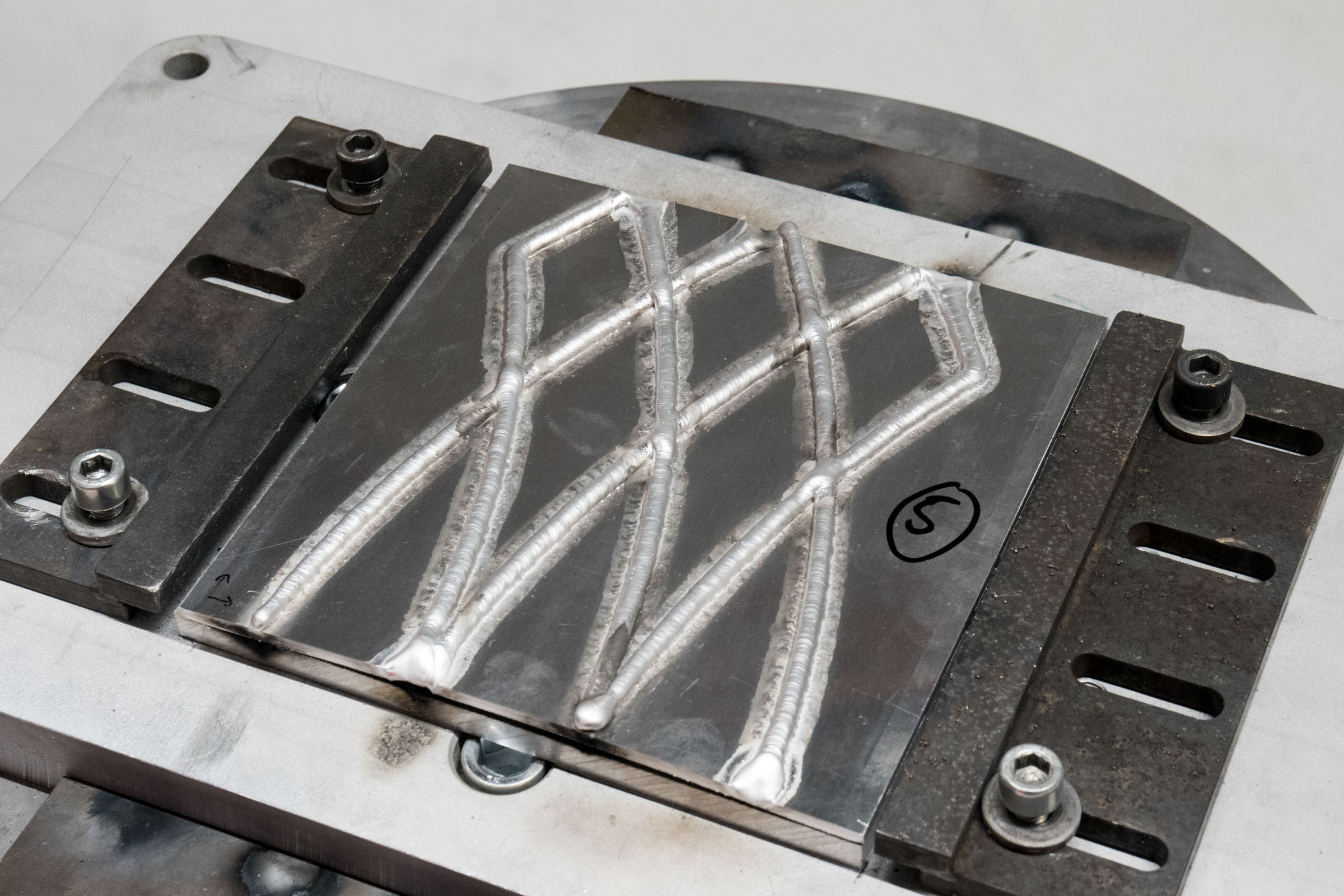

Thin-sheet metal is desirable for use in the context of freeform facades due to the ease with which they may be formed into shape. Advanced forming techniques, such as Multiple-point stretch forming and Single-Point incremental forming, have allowed designers to produce more radical geometric forms in this material. However, free-form facades are still rationalized as planar elements due to the relatively higher costs for forming and the increased complexity in connections and detailing to sub-structures. This Experiment looks at the potential for integrating detailing and stiffening ribs directly onto free-form sheet metal, intending to shift all the geometrical complexity out of supporting structures and entirely into the facade panel. This is done using Robotic Wire Arc Additive Manufacturing.