particle bed 3d printing

we mostly use particle bed 3d printing (SCA/SPI) to produce large, complex parts without formwork. the process builds directly from dry material and water — no waste, no molds.

it's a process

not a printer

we build large scale parts using a controlled, fully digital 3d fabrication process.

but, our 3d printers are only one piece of the system. what matters for a sucessful project is how intelligently design, material, and production systems are connected. that’s why we focus on workflow logic, hardware specs, and support with computational design.

reliable output comes from a reliable process.

particle bed 3d printing

we mostly use particle bed 3d printing (SCA/SPI) to produce large, complex parts without formwork. the process builds directly from dry material and water — no waste, no molds.

it's a process

not a printer

we build large-scale parts with a fully digital 3d fabrication process – but the printer is just one part. success depends on how intelligently design, materials, and production are connected. that's why we focus on workflow, hardware, and computational support.

more info

fully digital workflows

our production starts with a 3d model and flows directly into simulation and fabrication.

planning data, fabrication logic, and geometry all travel together in a single workflow.

closing the

digital chain

together with autodesk, we’ve developed a seamless workflow from BIM and CAD directly into our production systems. the entire process - from design input to finished part - runs as one coherent chain. we’ve built the tools to eliminate translation errors, streamline planning, and maintain full control. our team brings decades of experience handling complex 3d data for additive manufacturing and is happy to help.

fully digital workflows

our production starts with a 3d model and flows directly into simulation and fabrication.

closing the

digital chain

together with autodesk, we’ve developed a seamless workflow from BIM and CAD directly into our production systems. the entire process - from design input to finished part - runs as one coherent chain. we’ve built the tools to eliminate translation errors, streamline planning, and maintain full control. our team brings decades of experience handling complex 3d data for additive manufacturing and is happy to help.

large parts, made fast

we print parts up to 10 m³ in less than 5 hours — from structural elements to detailed, ornamental components. each part is generated from the same digital logic and built without formwork.

the zero waste

philosophy

every part is printed with only the material it needs — no support structures, no offcuts, no excess. hollow sections, internal ribs, and geometry-optimized volumes are standard in our process. even complex forms are printed directly, without formwork. this reduces raw material use, eliminates waste, and shortens production time.

large parts, made fast

we print parts up to 10 m³ in less than 5 hours — from structural elements to detailed, ornamental components. each part is generated from the same digital logic and built without formwork.

the zero waste

philosophy

every part is printed with only the material it needs — no support structures, no offcuts, no excess. hollow sections, internal ribs, and geometry-optimized volumes are standard in our process. even complex forms are printed directly, without formwork. this reduces raw material use, eliminates waste, and shortens production time.

quality built on data

we’ve been measuring every batch and every build we produced, yet — particle size, reaction heat, structural results. It’s continuous quality assurance feedback, built into our fabrication process.

a key to reliable

performance

each individual print job is tracked, tested, and evaluated.

we run particle distribution checks before printing, destructive tests after printing, and monitor reaction temperature during the process.

this data feeds into an AI model that predicts part quality in real time.

it’s how we moved from testing to industrial-grade reliability.

quality built on data

we’ve been measuring every batch and every build we produced, yet — particle size, reaction heat, structural results. It’s continuous quality assurance feedback, built into our fabrication process.

a key to reliable

performance

each individual print job is tracked, tested, and evaluated.

we run particle distribution checks before printing, destructive tests after printing, and monitor reaction temperature during the process.

this data feeds into an AI model that predicts part quality in real time.

it’s how we moved from testing to industrial-grade reliability.

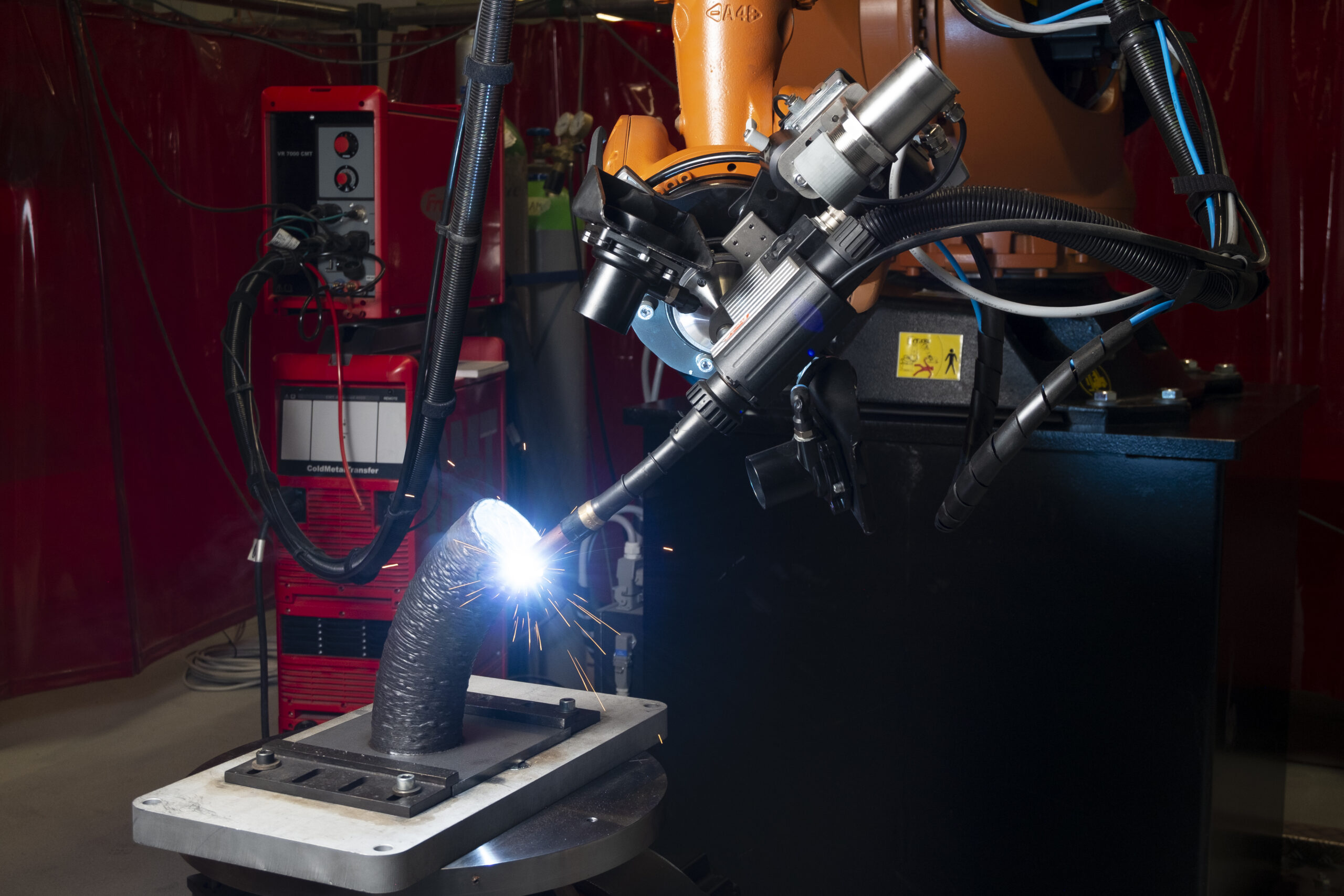

integrated robotics

we work with gantry-based machines, robotic arms and special machinery - depending on what is necessary in scale, part complexity, production environment or material system.

adjustable and

intelligent setups

each individual print job is tracked, tested, and evaluated.

our production setups can adapt to the project.

when needed, we develop custom workflows, hardware extensions, or toolchains — tailored to the part, product, or process.

robotic systems can be used not just for printing, but also for milling, part handling, painting, or hybrid operations.

the environment adjusts around the architecture — not the other way around.

integrated robotics

we work with gantry-based machines, robotic arms and special machinery - depending on what is necessary in scale, part complexity, production environment or material system.

adjustable and

intelligent setups

each individual print job is tracked, tested, and evaluated.

our production setups can adapt to the project.

when needed, we develop custom workflows, hardware extensions, or toolchains — tailored to the part, product, or process.

robotic systems can be used not just for printing, but also for milling, part handling, painting, or hybrid operations.

the environment adjusts around the architecture — not the other way around.