Type:

Country:

City:

Year:

Size:

Services:

Type:

Country:

City:

Year:

Size:

Services:

Facade

Germany

Regensburg

2020-2024

3000m²

Consultancy

Computational Design

Technology Development

Additive Manufacturing

Technology

Selective Cement Activation

Design Assist

Digital Modelling

Material Development

Type:

Country:

City:

Year:

Size:

Services:

Facade

Germany

Regensburg

2020-2024

3000m²

Consultancy

Computational Design

Technology Development

Additive Manufacturing

Technology

Selective Cement Activation

Design Assist

Digital Modelling

Material Development

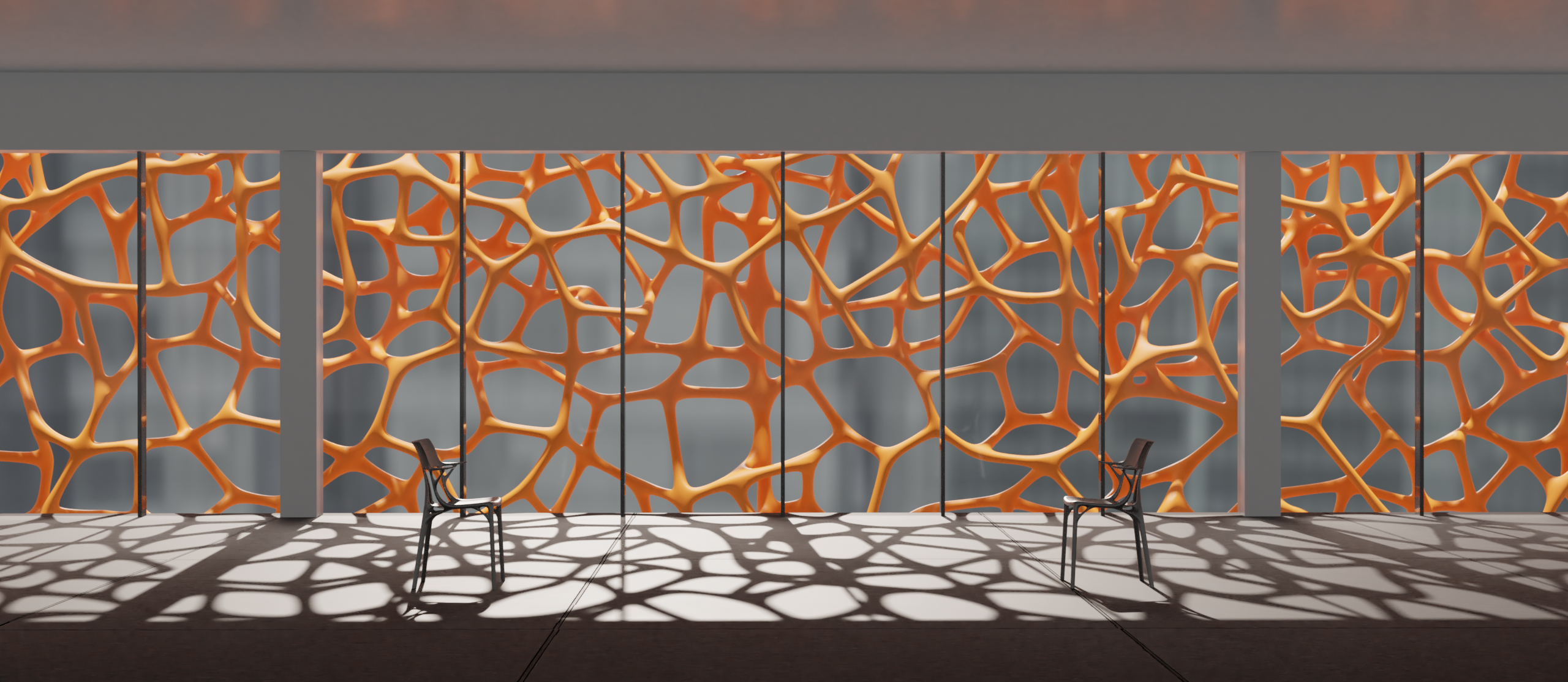

The next big project by additive tectonics is the development and construction of a facade-system for a new office building designed by Berschneider + Berschneider. By 2023, a 3,000 m² facade made of filigree intertwined structures is to be installed on the building, which, in addition to its outstanding appearance, is also functionally designed. The 3D-printed shading structure is made of 70% recycled glass and coated in a interesting orange tone: “Orange Vif” by the famous architect “le Corbusier”.

The next big project by additive tectonics is the development and construction of a facade-system for a new office building designed by Berschneider + Berschneider. By 2023, a 3,000 m² facade made of filigree intertwined structures is to be installed on the building, which, in addition to its outstanding appearance, is also functionally designed. The 3D-printed shading structure is made of 70% recycled glass and coated in a interesting orange tone: “Orange Vif” by the famous architect “le Corbusier”.

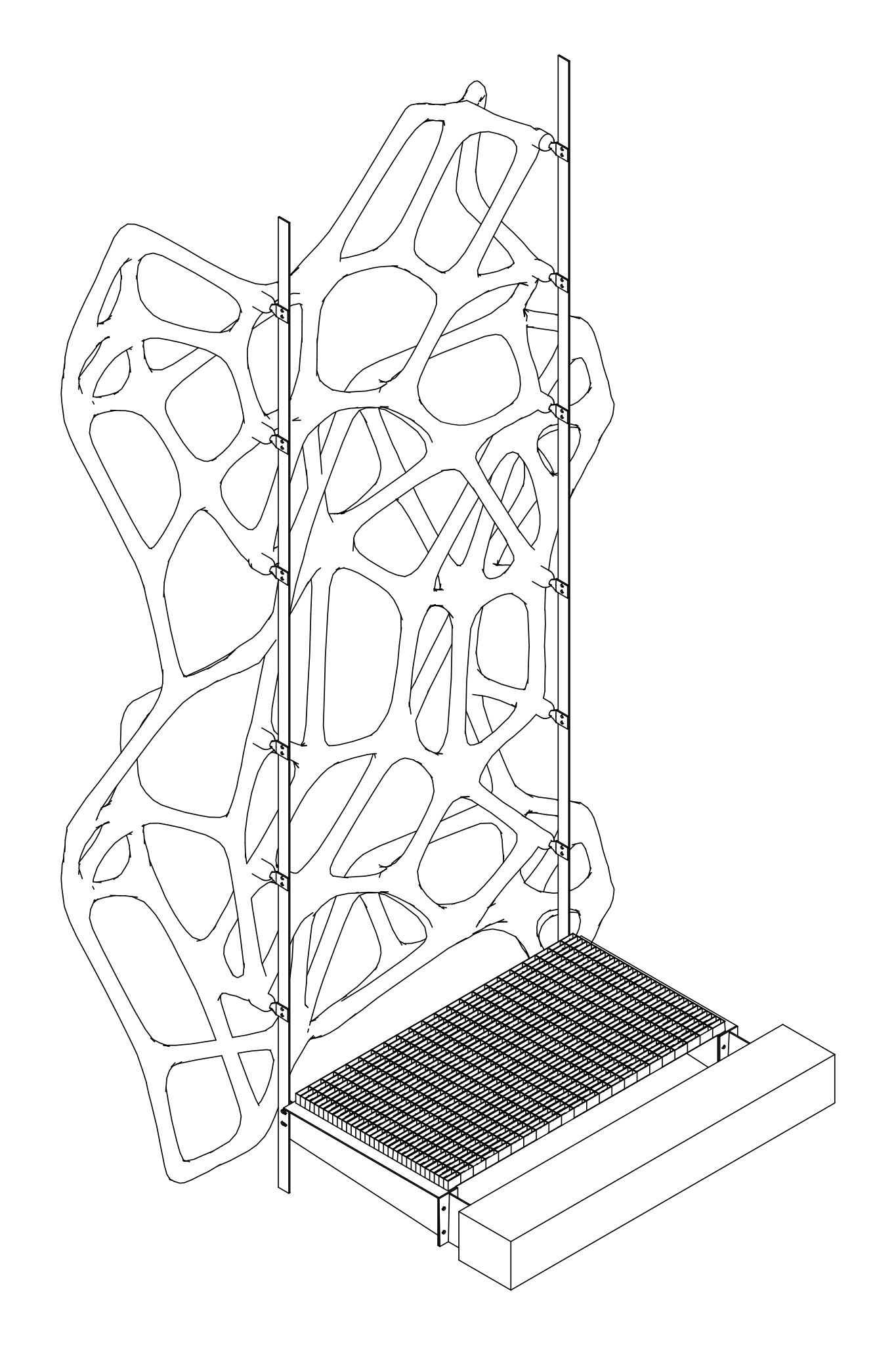

Our algorithm takes into account shading, penalisation, assembly and fabrication.

In a first step, points are generated along the kubatur of the fassade, then these points are intelligently connected, if a group of points fulfill certain performance criteria, like structural integrity, distance and angle towards each other. If no solution is found, the points rearrange.

Once the performance goal is met, a network of lines is generated that is used as a skeleton for the volume of the fassade. Before the actual geometry is created, the algorithm divides the structure into fabricatable panels, taking into account construction and fabrication restrictions for each individual panel.

Finally we will fabricate 636 different panels, each of them around 5 m² in dimension.

Our algorithm takes into account shading, penalisation, assembly and fabrication.

In a first step, points are generated along the kubatur of the fassade, then these points are intelligently connected, if a group of points fulfill certain performance criteria, like structural integrity, distance and angle towards each other. If no solution is found, the points rearrange.

Once the performance goal is met, a network of lines is generated that is used as a skeleton for the volume of the fassade. Before the actual geometry is created, the algorithm divides the structure into fabricatable panels, taking into account construction and fabrication restrictions for each individual panel.

Finally we will fabricate 636 different panels, each of them around 5 m² in dimension.